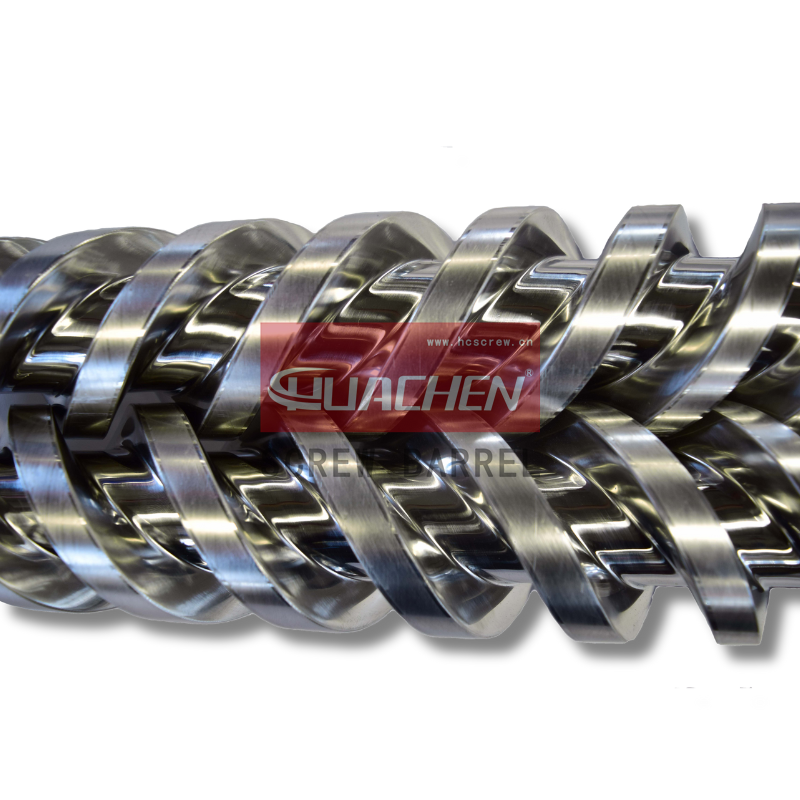

Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

● Min. Order (MOQ): Set

● Pipe extrusion ● Sheet extrusion

● Profile extrusion ● Recycling extrusion

● Compounding extrusion ● Cable / wire extrusion

● Blown film / Lamination ● Colour liner / Coating extrusion

● Nonwoven fabric extrusion ● Monofilament / staple fibre extrusion

● Cast film ● Blow Moulding ● Injection Moulding

You Need Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel at Good Price!

- Product Detail

Our super wear-resistant bimetallic alloy coating screw barrels are specifically engineered for high output extruders, offering unmatched durability and efficiency. The advanced bimetallic alloy coating ensures maximum wear resistance, making these screw barrels ideal for handling abrasive materials in plastic extrusion. By installing our high-performance screw barrels, you can achieve consistent output and reduce maintenance downtime, significantly enhancing your entire production efficiency.

Key Benefits of Bimetallic Alloy Coating for High Output Extruders

- 1. Wear Resistance: The bimetallic alloy coating provides exceptional resistance to wear, significantly extending the lifespan of the screw barrel.

- 2. Durability: Constructed with high-quality materials, our screw barrels are designed to withstand the harsh conditions of high output extrusion processes.

- 3. Efficiency: Optimized design and superior materials ensure efficient extrusion, leading to higher output and reduced energy consumption.

- 4. High Output Capabilities: Engineered for high performance, our screw barrels are ideal for high volume production, maintaining consistent quality and performance.

Features of Our Super Wear-Resistant Screw Barrels

High Durability and Performance

Our super wear-resistant bimetallic alloy coating screw barrels are manufactured from premium materials such as 38CrMoAlA and treated with advanced nitriding and bimetallic alloy coatings. These processes enhance the hardness and wear resistance of the screw barrels, ensuring they can handle even the most abrasive materials. The plasma nitriding surface hardness ranges from HV 1000-1100, with a nitriding depth of ≥ 0.7 mm, providing excellent durability.

Suitable Applications and Use Cases

Our screw barrels are versatile and suitable for a wide range of applications, including:

- 1. Pipe Extrusion: Ideal for producing PVC, PE, HDPE, and other plastic pipes.

- 2. Sheet Extrusion: Perfect for creating plastic sheets and panels.

- 3. Profile Extrusion: Suitable for various plastic profiles.

- 4. Recycling Extrusion: Efficiently handles recycled materials.

- 5. Compounding Extrusion: Excellent for mixing and compounding different materials.

- 6. Cable/Wire Extrusion: Ensures high-quality cable and wire production.

- 7. Blown Film/Lamination: Ideal for producing high-quality films and laminates.

- 8. Nonwoven Fabric Extrusion: Suitable for nonwoven fabric production.

- 9. Monofilament/Staple Fibre Extrusion: Excellent for producing fibers.

- 10. Cast Film: Perfect for creating cast films.

- 11. Blow Moulding: Ideal for producing hollow plastic parts.

- 12. Injection Moulding: Ensures precise and efficient injection molding processes.

Our Bimetallic Alloy Screw Barrel Standards

- 1. Substrate Treatment Grade: 38CrMoAlA + nitriding for 96-120 hours.

- 2. Bimetallic Grade: 38CrMoAlA + bimetallic alloy.

- 3. Bimetallic Alloys: Includes nickel-based alloys, cobalt-based alloys, molybdenum-based alloys, cobalt tungsten carbide hard alloys, and ceramic alloys.

- 4. HC-A Grade: Tungsten carbide 40%.

- 5. HC-B Grade: Tungsten carbide 25%.

- 6. HC-C Grade: Tungsten carbide 15%.

- 7. Chrome Plating Screw

- 8. Ceramic Alloy Screw

Types of Bimetallic Alloy Screw

- – Type 1: Screw flights welded with bimetallic alloy, commonly used in the manufacturing industry. It is cost-effective and suitable for less problematic plastics.

- – Type 2: Entire screw coated with bimetallic alloy, providing longer working life but at a higher cost.

Types of Bimetallic Alloy Barrels

- – Type 1: Grooved and coated bimetallic alloy barrel. Grooves are drawn in the barrel bore, sprayed with bimetallic alloy compound, and polished smoothly.

- – Type 2: Centrifuge-cast alloy barrel. Uses a centrifugally cast alloy base resistant to wear and corrosion, strengthened with centrifugal casting.

Premium Materials and Manufacturing Specifications

- 1. Core Materials: Premium 38CrMoAlA

- 2. Plasma Nitriding Surface Hardness: HV 1000-1100

- 3. Plasma Nitriding Depth: ≥ 0.7 mm

- 4. Nitriding Fragility: Less than Grade I.

- 5. Surface Roughness: Ra 0.4 μm

- 6. Screw Linearity: ≤ 0.015 mm

- 7. Bimetallic Alloy Depth: 2-4 mm

- 8. Bimetallic Alloy Surface Hardness: ≥ HRC 62

For more detailed information, visit our Super Wear-Resistant Bimetallic Alloy Coating screw barrel parameters page.

How to Order from HUACHEN Screw

Ready to enhance your production with HUACHEN’s advanced Bimetallic Alloy Coating Screw Barrel? Follow our detailed Step-by-Step Guide to Order from HUACHEN Screw Barrel for a seamless purchasing experience.

For inquiries or more information about our Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders, please contact us.

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading manufacturer of Bimetallic Alloy Coating screw barrels in Zhoushan, China. With extensive experience in designing and processing plastic machinery accessories, we offer a wide range of services including custom screw barrels, rebuilding, modification, and upgrades. Our products are trusted by customers worldwide. To learn more about our company, our history, and the services we offer, please visit our About Us page.