Enhance Your Extrusion Efficiency with HUACHEN’s Advanced SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws

Date:2024-5-22 Author:hcscrew

In the dynamic world of plastics and polymers, efficiency and performance are paramount. To meet the demands of modern extrusion processes, manufacturers need cutting-edge technologies that can deliver superior results consistently. This is where HUACHEN Screw Manufacturing Co., Ltd. steps in with its advanced SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws.

Introduction to HUACHEN Screw Manufacturing Co., Ltd.

At HUACHEN Screw, we take pride in our commitment to innovation and quality in screw barrel technology. With years of experience and a dedicated team of professionals, we strive to push the boundaries of what’s possible in extrusion technology.

HUACHEN’s Advanced Technologies

SKD Sleeve Fitted Barrels

Our SKD Sleeve Fitted Barrels are engineered to provide unmatched wear resistance, cost-effectiveness, and performance. By inlaying a special sleeve made of SKD11 material into the barrel bore, we enhance the durability and longevity of the barrel, reducing the need for frequent replacements. Despite the higher cost associated with their high performance and the difficulty of machining them, SKD Sleeve Fitted Barrels offer a significant return on investment by improving overall production efficiency and reducing downtime.

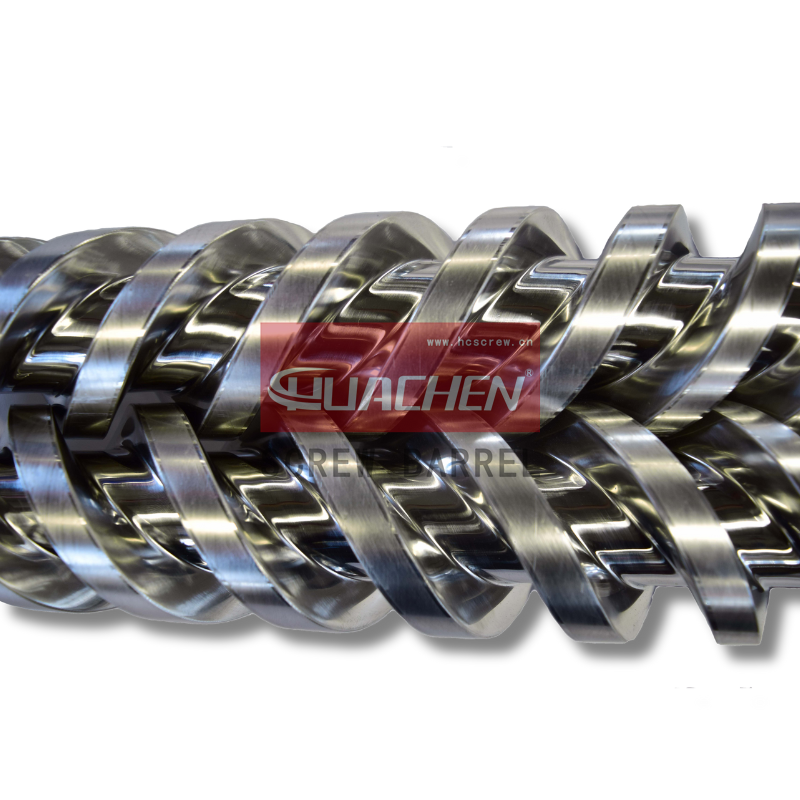

Super Wear-Resistant Alloy Screws

Our Super Wear-Resistant Alloy Screws are the result of extensive research and development. Developed independently by HUACHEN Screw, these alloy screws offer superior wear and corrosion resistance compared to traditional alloy screws on the market. With solid workmanship and reduced risk of alloy shedding, our alloy screws are designed to withstand the most demanding extrusion processes, ensuring consistent performance and quality.

Applications and Target Markets

Our advanced technologies cater to a wide range of industries and products, including PVC flooring, decorative sheets, pipes, profiles, wood-plastic products, and HDPE products. Whether you’re extruding high-filled PVC or HDPE materials, our SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws are engineered to meet your specific needs and deliver exceptional results.

Technical Excellence and Historical Development

The development of our SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws has been marked by technical challenges and evolution. From the initial high failure rate and quenching difficulties to the complex machining process, we have overcome numerous obstacles to deliver high-quality products that exceed industry standards. With our mature process and advanced technology, we have streamlined production and mass-produced SKD sleeved barrels to serve customers worldwide.

Real-Life Examples and Benefits

Case studies have shown significant improvements in production volume and product quality with our advanced technologies. Customers have reported increased extrusion volume, reduced screw barrel damage, and long-term cost savings. By investing in HUACHEN’s SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws, manufacturers can achieve higher efficiency, lower maintenance costs, and ultimately, greater profitability. The advantages of using our SKD sleeved barrel screws are high plasticisation, high production and high quality.

Acquiring HUACHEN’s SKD Sleeve Barrels and Super Wear-Resistant Alloy Screws

We work closely with global extruder companies to provide customers with access to our advanced technologies. Whether you’re looking to upgrade your existing extruder or invest in new equipment, our team is here to help you find the right solution for your needs. With our cost-effective and performance-enhancing products, you can take your extrusion process to the next level and stay ahead of the competition.

Conclusion

At HUACHEN Screw Manufacturing Co., Ltd., we are committed to advancing screw barrel technology and empowering manufacturers to achieve their production goals. With our SKD Sleeve Fitted Barrels and Super Wear-Resistant Alloy Screws, you can enhance your extrusion efficiency, improve product quality, and drive long-term success. Visit our booth at international exhibitions to learn more about how HUACHEN’s advanced technologies can benefit your business.

Why Choose HUACHEN Screw Barrel?

As a leading bimetallic alloy twin screw barrel manufacturer in Zhoushan, China, HUACHEN Screw Barrel is committed to delivering products with superior plasticization, anti-wear, and corrosion resistance. Our state-of-the-art manufacturing base on Jintang Island, Zhejiang Province, is equipped with advanced CNC screw barrel production equipment, ensuring top-notch quality for every product. Our extensive range includes conical twin screw barrels, parallel twin screw barrels, and specialized SKD screw barrels designed for PVC, PE, PP, PET, and PA applications. >>Learn more about our company

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;