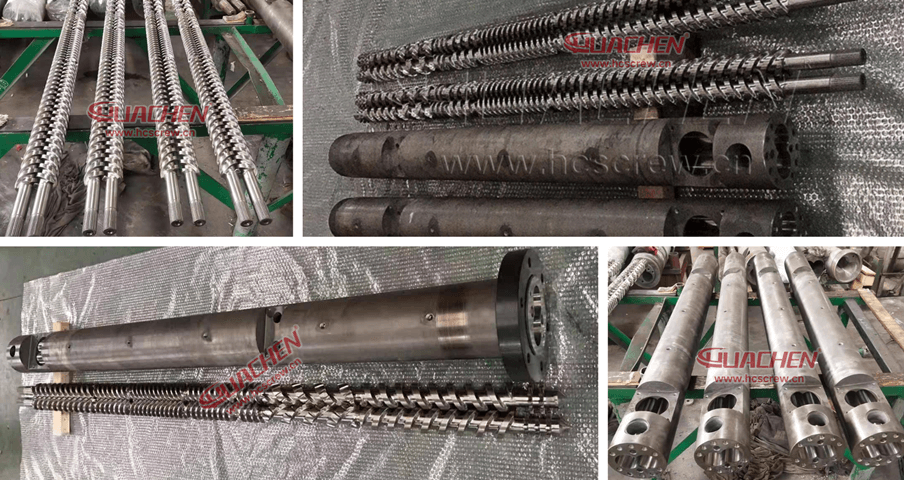

PVC Pipe Parallel Twin Screw Barrel

● PVC / UPVC / RPVC / CPVC

● Pipe making extrusion, virgin or recycled materials, compound materials

● Filler percentage with 30-50%, 50-100%, 100-150%, 150-200%

● Min. Order (MOQ): 2 screws + 1 barrel

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw

You need better parallel twin screw barrel set at good price!

- Product Detail

Upgrade Your PVC Pipe Extrusion Process with HUACHEN’s Parallel Twin Screw Barrels Today!

Discover HUACHEN’s state-of-the-art parallel twin screw barrels, specifically designed for producing high-quality PVC pipes. Experience unparalleled efficiency, superior material handling, and reduced production costs with our innovative technology.

Why Choose HUACHEN’s Parallel Twin Screw Barrels?

- –Exceptional Quality: Crafted from premium 38CrMoAlA nitrided steel, tempered, and nitrided for maximum durability and wear resistance. Bimetallic alloy anti-wear treatment is applied to the top surface of the screw flight in the extruding, venting, melting, and mixing sections. The barrels can be supplied with a bimetallic alloy groove surface strengthening process to enhance abrasion resistance.

- –Optimized Performance: Engineered for low shear, high mixing, and efficient conveying, ensuring superior plasticization and extrusion. Our optimized screw designs help mix the PVC pipe material well, increase plasticization, improve extrusion volume, and provide excellent venting performance, resulting in superior PVC pipe surfaces.

- –Versatile Applications: Perfect for various PVC composite products, including solid wall PVC pipes, corrugated wall PVC pipes, UPVC pipes, and CPVC pipes.

Key Features

Our parallel twin screw barrels are tailored to handle the high calcium powder fill ratio and poor material flow of PVC pipe materials, ensuring consistent extrusion and better feeding. Constructed from high-quality alloy steel with bimetallic alloy processing and ceramic tungsten coating, these barrels offer extended life and superior durability. Standard models and designs allow for seamless integration into existing systems. The barrel with SKD sleeves fitted offers more SKD sleeve lengths for customization, providing flexibility and extended service life.

Four Levels of Anti-Wear Solutions

Level 4: SKD sleeve fitted barrel and hard chrome coating screws for premium performance.

Level 3: Centrifugal cast alloy barrels and hard chrome coating screws for enhanced durability.

Level 2: Bimetallic alloy barrels and bimetallic screws for robust wear resistance.

Level 1: high strength nitrided barrel and screws for excellent efficiency and longevity.

Applications

- -Solid wall PVC pipe extrusion machine

- -Corrugated wall PVC pipe extrusion machine

- -UPVC pipe extrusion machine

- -CPVC pipe making machine

Model Specifications

| Model | Screw diameter (mm) | L/D ratio | Screws rotation speed ( RPM) | Extruder motor power | PVC capacity (kg/h) |

|---|---|---|---|---|---|

| HCPS-75 | 75 | 26-36 | 0-45 | 45-55 | 220-350 |

| HCPS-90 | 90 | 26-36 | 0-45 | 55-75 | 280-460 |

| HCPS-110 | 110 | 26-36 | 0-45 | 75-110 | 350-650 |

| HCPS-120 | 120 | 26-36 | 0-45 | 110-132 | 500-800 |

| HCPS-130 | 130 | 26-36 | 0-45 | 132-145 | 680-1000 |

Popular PVC Pipe Parallel Twin Screw Barrel Stock Models

| φ52/25 | φ60/25 | φ75/36 | φ90/36 | φ107/28 |

| φ107/28 | φ120/26 | φ130/28 | φ135/28 | φ160/33 |

Fast Customisation

| Extrusion brand | Screw barrel models |

|---|---|

| CINCINNATI | AGROS – 72 / 93 / 114 / 136 |

| KRAUSS MAFFEI | KMD – 75 / 90 / 110 / 130 |

| BATTENFIELD | BEX – 65 / 68 / 90 / 92 / 107 / 130 |

| KABRA | 52 / 65 / 68 / 90 / 92 / 110 / 135 / 168 |

| WINDSOR | KTS – 52 / 65 / 71 / 91 / 110 / 135 |

Premium Materials

- –Diameters available: 35-110 mm

- –L/D ratio available: 15 to 36

- –Core Materials: Premium 38CrMoAlA, SKD11, SKD61

- –Plasma Nitriding Surface Hardness: HV 1000-1100

- –Plasma Nitriding Depth: ≥ 0.7 mm

- –Nitriding Fragility: Less than Grade I

- –Surface Roughness: Ra 0.4 μm

- –Screw Linearity: ≤ 0.015mm

- –Alloy Depth: 1.5-4mm/4-6 mm

- –Alloy Surface Hardness: ≥ HRC 61

- –SKD Sleeve Surface Hardness: HRC≥62

- –SKD Sleeve Thickness: 6-10mm

For detailed parameters, visit our PVC Pipe Parallel Twin Screw Barrel Parameters.

Fast and Reliable Delivery

- –Standard Models: Ready within 7 days.

- –Peak Season Lead Time: Up to 45 days.

- –Off-Season Lead Time: Within 33 days, depending on part complexity.

How to Order from HUACHEN Screw

Ready to enhance your production with HUACHEN’s advanced parallel twin screw barrels? Follow our detailed Step-by-Step Guide to Order from HUACHEN Screw Barrel for a seamless purchasing experience.

For inquiries or more information about our PVC pipe parallel twin screw barrels, please contact us.

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading manufacturer of parallel twin screw barrels in Zhoushan Jintang. Our comprehensive services include drawing rebuilding, design, modification, and customized screw barrels. Trusted globally, our products ensure top-tier performance and durability. If you have any questions, please feel free to contact us. To learn more about our company and services, please visit our About Us page.