Is Your Plastic Product Requiring Nitrided Or Bimetallic Screw?

Date:2022-8-04 Author:hcscrew

When it comes to choosing the right screw for your plastic extrusion process, understanding the differences between nitrided and bimetallic screw is essential. This guide will help you determine whether a nitrided screw or a bimetallic screw is the best fit for your needs.

Nitrided Screw vs. Bimetallic Screw

Nitrided Screw

Nitrided screws are hardened through a process called nitriding, where nitrogen atoms are diffused into the surface of the metal. This process results in screws that are stronger, more durable, and more resistant to corrosion than untreated steel screws.

Bimetallic Screw

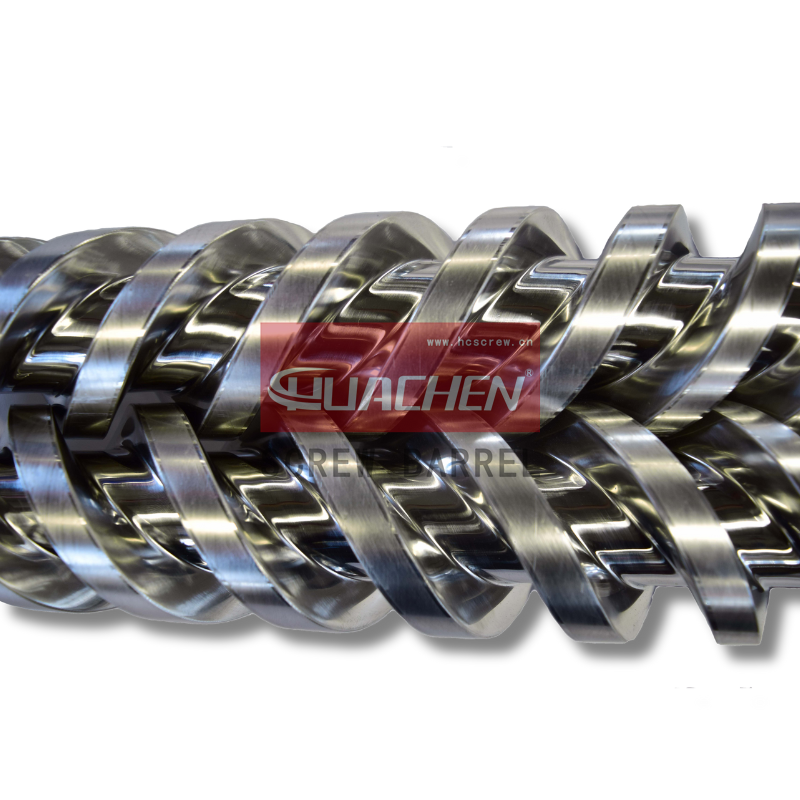

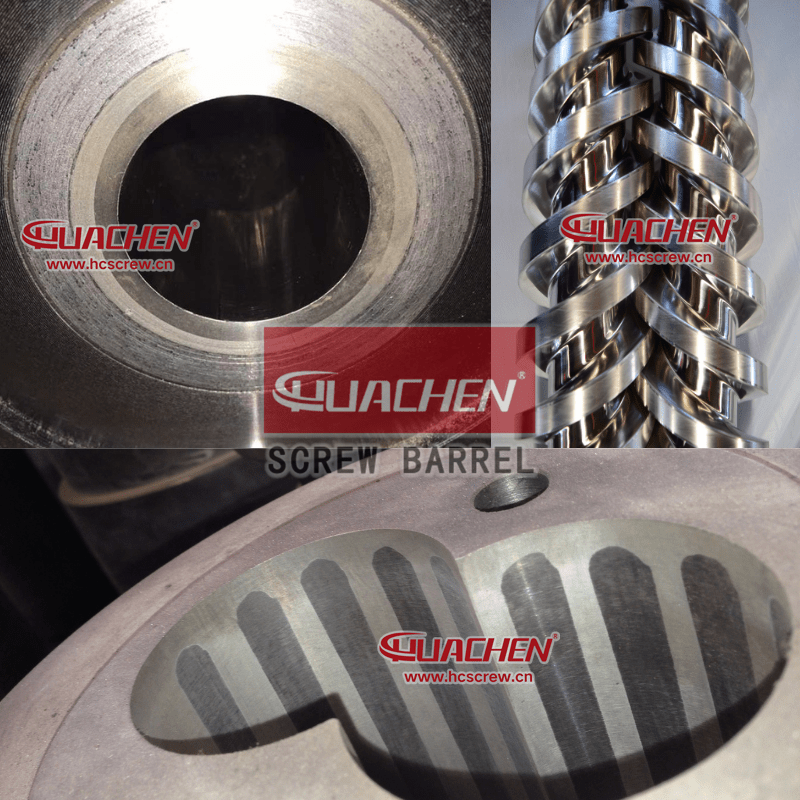

Bimetallic screw are constructed from two different metals, each offering unique properties. These screw are designed for applications requiring high strength and corrosion resistance. The combination of metals allows for enhanced performance in demanding extrusion environments.

Why Are Nitrided Screw Popular?

Nitrided screw remain popular due to their economical nature and sufficient performance for many applications. In countries like Germany, the USA, and Japan, nitrided steel screw are still widely used, especially in smaller and medium-sized extruders.

Why Choose Bimetallic Screw?

With the increasing demands of modern extrusion processes, bimetallic screw have become the preferred choice. They offer superior wear resistance and durability, making them ideal for high-pressure, high-speed extrusions.

Detailed Comparison: Nitrided vs. Bimetallic Screw

1. Nitrided Screw

Advantages:

- – Economical

- – Suitable for various applications

Disadvantages:

- – Limited wear resistance

- – Susceptible to corrosion

- – Thin nitrided layer (around 0.5 mm) wears away quickly

2. Bimetallic Screw

Advantages:

- – High wear resistance

- – Excellent corrosion resistance

- – Long lifespan

Disadvantages:

- – Higher initial cost

Common Bimetallic Screw Treatment Methods

1. Hard Chrome Plating

This chemical treatment involves coating the screw with a thin layer of chrome, improving surface finish and corrosion resistance. However, the plating process is demanding and can lead to issues if not performed correctly.

2. Surface Flame Hardening

A cost-effective treatment where the screw surface is hardened using a flame, achieving a quenching depth of 2-3 mm. This method is suitable for large screws.

3. Bimetallic Particle Overlay

This method involves welding a layer of bimetallic particles onto the screw surface using techniques like electric arc welding or plasma welding. The overlay improves the screw’s hardness and wear resistance.

4. Spray Coating with Bimetallic Particles

This advanced treatment involves spraying a coating of bimetallic particles onto the screw surface, enhancing wear resistance and durability.

5. Other Treatments

Carburizing and boron carburizing are also used to enhance screw performance, though these methods are less common and still under development.

Conclusion

While nitrided screw are still in use, bimetallic screw offer superior performance for modern extrusion processes. Choosing the right screw depends on your specific needs and the demands of your production environment.

For expert advice on selecting the best screw barrel for your application, contact HUACHEN Screw, a leading screw barrel manufacturer in China. We offer a wide range of customized screw barrels to meet your unique requirements.

About HUACHEN

HUACHEN Screw has been a leading bimetallic alloy screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the top companies in designing and processing high-strength extrusion spare parts screw barrels, HUACHEN Screw provides a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has successfully exported and supplied screw barrels to customers worldwide.

For more information, visit HUACHEN Screw.

You May Also Like

| Bimetallic Alloy Screw Barrel ↗ – Get details and the latest price of bimetallic alloy screw barrels. |

| Hard Chrome Plating Screw Barrel ↗ – Discover our range of hard chrome plating screw barrels. |

| Ceramic Coating Alloy Screw Barrel ↗ – Learn about our ceramic coating alloy screw barrels for SPC RVP. |

| SKD Screw Barrel ↗ – Find out more about our SKD sleeve fitted screw barrels for high-filled PVC twin screw extrusion. |

Tags

HUACHEN Screw Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

Tag Clound

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;