About us

- Company profile

- Technical Innovation

- Order service flow

- Screw barrel parameters

- SKD inlay bushing barrel

- Screw barrel process flow

- Exhibition

About us

- Address:NO.1 Liuhang Road, Xihou Industrial Zone, Jintang Town, Dinghai District, Zhoushan

- TEL:86-580-8052288

- FAX:86-580-8053878

- ZIPCODE:316031

- E-mail: info@hcscrew.cn

- URL:www.hcscrew.cn

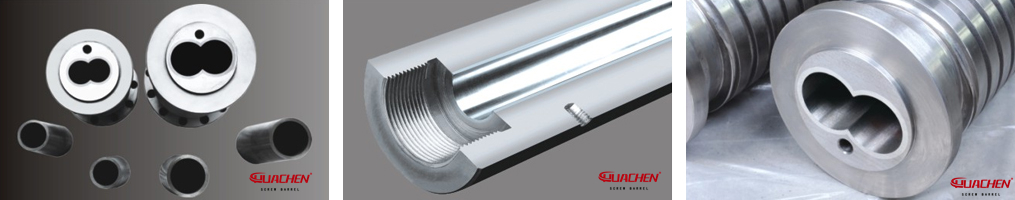

SKD inlay bushing barrel

SKD Inlay Bushing Barrel, SKD Sleeve Fitted Barrel, or SKD Sleeve Insert Barrel

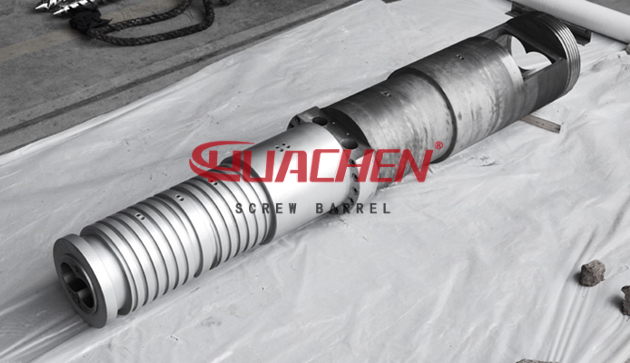

In 2012, HUACHEN Screw pioneered the development of a conical twin screw barrel with tool steel SKD sleeve or bush inserts to enhance resistance to corrosion and wear. The wear-resistant material SKD is used to create a conical-eight-shaped bore sleeve, which is then integrated into the bore of the conical twin barrel to ensure a tight fit with the inner wall. This design is particularly suited for producing high-filled PVC products due to the conical twin barrel’s superior wear resistance.

SKD Sleeve Fitted Barrels

This highly wear-resistant base material is typically crafted from tool steels SKD11 (equivalent to D2) and SKD61 (equivalent to H13). In the Chinese market, these are known as SKD screw barrels or SKD sleeve fitted barrels, used in complete sets of twin screw conical barrels with an SKD barrel.

SKD sleeve fitted barrels are high-performance barrels that require precise machining. The entire barrel bore must remain flat and smooth to prevent sticking and ensure optimal plasticization of polymers. The inlay plane of the SKD inner bushing must be flat and smooth, presenting a significant technical challenge. The SKD11 sleeve is embedded in the inner wall of the barrel extruding section, which is prone to wear when producing highly filled PVC products. Depending on the required wear resistance area, the SKD11 sleeve fitted barrel is available in three different lengths: one-zone SKD barrel, two-zones SKD barrel, and full coverage SKD barrel.

Advantages of the SKD Sleeve Fitted Barrel from HUACHEN Screw Barrel Factory

- 1. The wear-resistant SKD11 sleeve is tightly bonded to the barrel, preventing loss of the alloy layer.

- 2. Enhanced corrosion resistance.

- 3. Improved wear resistance.

- 4. Increased surface hardness of the barrel bore.

- 5. Suitable for the extrusion of high-filled materials, effectively extending the range of materials processed.

- 6. High productivity and energy efficiency, reducing production costs.

Click here to see the actual results.

- 1. Wear Resistant Barrel Sleeve, SKD Sleeve or Bush

- 2. SKD Sleeve Fitted Barrel

- 3. Removable SKD Sleeve Fitted Technology for Conical Twin Screw Barrel

- 4. Difference Between SKD11 And SKD61 On Process Screw Barrel