How to Install a Conical Twin Screw Barrel on an Extruder

Date:2024-5-21 Author:hcscrew

Learn how to properly install a conical twin screw barrel on an extruder with this detailed guide from HUACHEN Screw Barrel, a leading twin screw barrel manufacturer. Ensure optimal performance and longevity of your extrusion equipment with our expert tips.

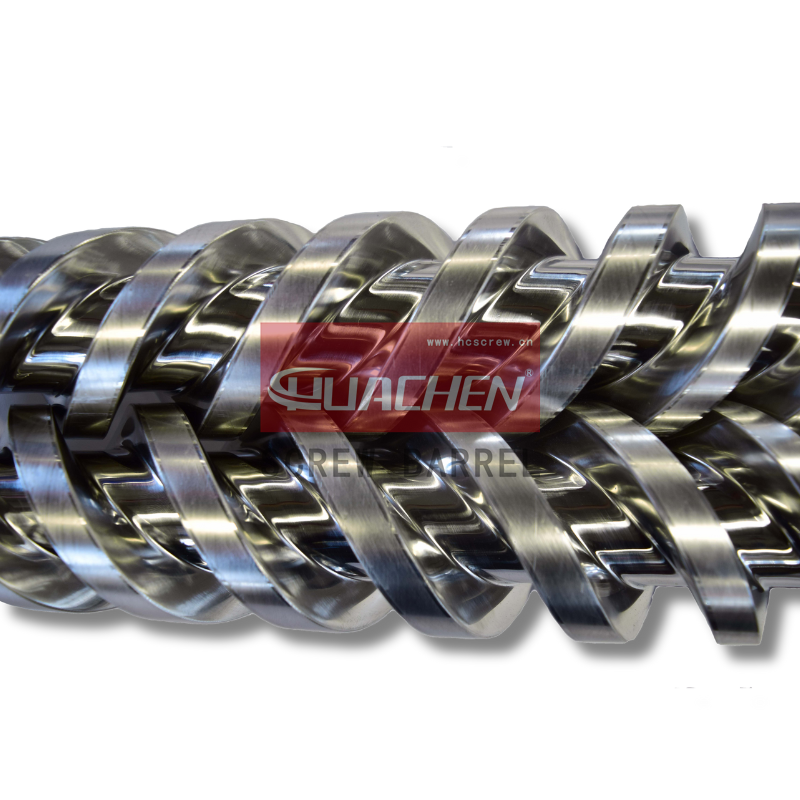

For users of conical twin screw barrels, understanding the correct installation process is crucial. Conical twin screw extrusion offers significant benefits, particularly for manufacturing high-filler PVC products. At Zhejiang Huachen Screw Manufacturing Co., Ltd, we specialize in providing high-quality screw barrels to meet your extrusion needs.

Why Choose HUACHEN Screw Barrel?

As a leading bimetallic alloy twin screw barrel manufacturer in Zhoushan, China, HUACHEN Screw Barrel is committed to delivering products with superior plasticization, anti-wear, and corrosion resistance. Our state-of-the-art manufacturing base on Jintang Island, Zhejiang Province, is equipped with advanced CNC screw barrel production equipment, ensuring top-notch quality for every product. Our extensive range includes conical twin screw barrels, parallel twin screw barrels, and specialized SKD screw barrels designed for PVC, PE, PP, PET, and PA applications.

Step-by-Step Guide to Installing a Conical Twin Screw Barrel

Proper installation of your conical twin screw barrel is essential for optimal performance and longevity. Follow these steps to ensure a successful installation:

Step 1: Install the Conical Twin Screw Barrel

1. Ensure the Barrel is Horizontal

- First and foremost, ensure that the frame of the conical twin screw extruder is perfectly horizontal. Verify that it is securely fastened.

Key Point 1: Make sure the conical twin screw barrel is horizontal!

Ensuring the barrel is horizontal is essential. It ensures that the pressure between the twin screws and the barrel is evenly distributed. If the barrel is not horizontal, the screw under more pressure will wear out faster. This can lead to issues such as one of the screws cracking prematurely, which is often mistakenly attributed to quality problems.

Key Point 2: How do you make the barrel horizontal?

In the image above, look at the clearance of 6, which is the gap between the extruder gearbox and the barrel’s end. Make sure that all of the mounting distances add up to 1=2, 3=4, 5=6, which indicates that your conical twin screw barrel is horizontal. If it doesn’t stay the same, make the necessary adjustments to the extruder bracket.

2. Install the Barrel Support Frame

- Place the front and rear support frames of the barrel in the correct positions. Set the barrel on the extruder platform and secure the front and rear moving devices by tightening the fixing screws.

3. Standard Barrel Height

- Measure the center height of the front and back ends of the conical twin screw barrel using a height ruler. Use the center height of the gearbox’s distribution box as the reference.

4. Gearbox to Barrel Connection

- Push the barrel to connect it with the distribution box. Double-check to ensure the connection is correct.

Step 2: Install the Conical Twin Screws

1. Verify Correct Barrel Installation

- Open the large nut of the conical twin screw barrel and remove the barrel. Insert the two conical twin screws into their respective holes, ensuring the left and right screws are placed correctly. Note that the screws rotate in opposite directions, outward from the center.

2. Locate the Reference Point on the Screw Shank

- Identify the reference point on the screw shank’s spline. The reference points of the two screws should be vertically aligned and facing upward.

3. Locate the Reference Point on the Output Shaft Shank

- Find the reference point on the flat key of the output shaft spline. Align these points with the reference points on the screws, ensuring they are vertically upward and side by side.

4. Align the Screws

- Insert the screws into the barrel until the required distance is achieved. The small end of the screw should be at the front of the barrel.

Distance Table for Different Models:

| Model | 45/100 | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

|---|---|---|---|---|---|---|

| N1 (mm) | 3-5 | 4-6 | 4-6 | 4-6 | 7-9 | 8-10 |

5. Adjust Screw Distance

- Push the small head screw tip into the barrel’s small end, adjusting the standard screw barrel spacing according to the distance table. Hold the left screw in place while adjusting the right screw back and forth to the correct position.

6. Install Gaskets and Secure Screws

- Install two gaskets at the ends of the screws and secure them with fixing screws. Tighten the large barrel nut and secure the screws to the extruder gearbox distribution box. Adjust the screws to ensure proper alignment and distance.

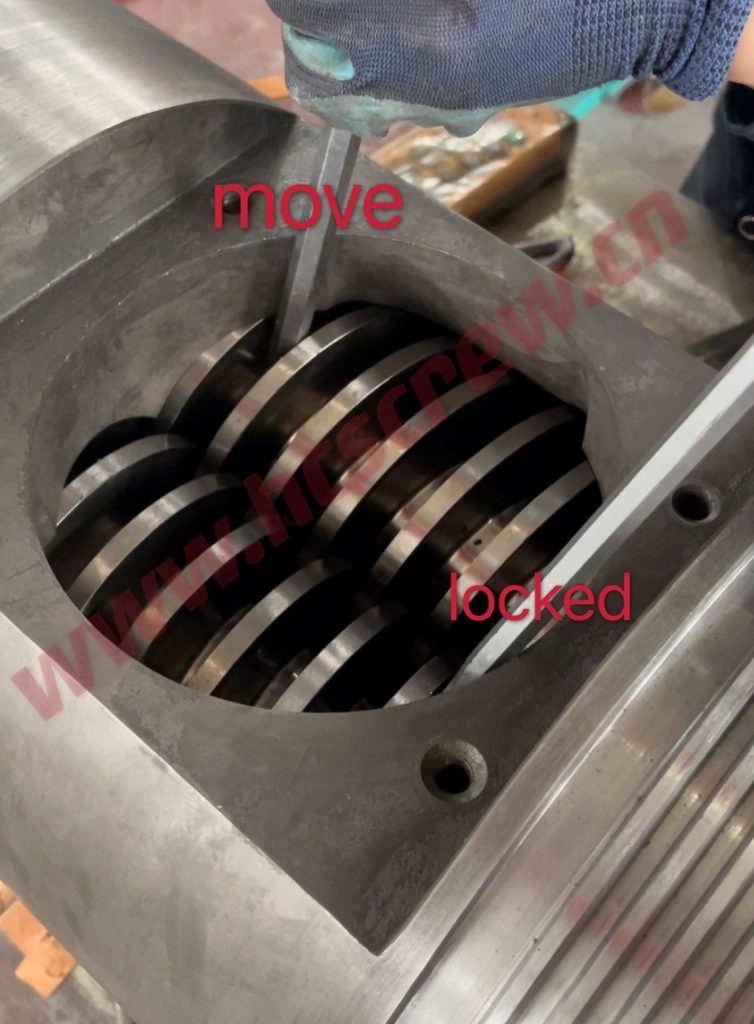

Key Point: Ensuring Proper Screw Alignment

Push the left screw all the way to the back of the gearbox. Use tools to lock the left screw in place while adjusting the right screw. Both screws must be adjusted to ensure they reach the gearbox at the same distance.

7. Adjust Screw Shank Gaskets

- Adjust the thickness of the gaskets at the ends of the screws. Ensure that the distances (F1 and F2) are equal, making F1=F2=1/2L.

8. Install the Striker Plate

- Install the barrel striker plate, screw, and fixed set (or external circulation oil sleeve). Align the screw’s reference point with the output shaft of the distribution box. Tighten the large nut to secure the installation.

Why Proper Installation Matters

Proper installation of your conical twin screw barrel is vital for ensuring efficient and effective operation of your extrusion equipment. Misalignment or improper installation can lead to uneven pressure distribution, accelerated wear, and potential equipment failure. By following the steps outlined above, you can maximize the lifespan and performance of your conical twin screw barrel, ensuring consistent quality and productivity in your extrusion processes.

Contact HUACHEN Screw Barrel for Expert Guidance

At HUACHEN Screw Barrel, we are dedicated to providing our customers with high-quality screw barrels and exceptional service. If you need further assistance or a video demonstration of the installation process, feel free to contact us. Our team of experienced technicians is here to help you achieve the best results with your extrusion equipment.

YOU MAY ALSO LIKE

| Conical Twin Screw Barrel ↗ Get latest & most competitive prices on China conical twin screw barrel, extruder barrels, extruder screw, bimetallic screw, SKD barrels. |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extruder screw barrel you are using, the type of product you are producing, and the amount of filling such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your SKD screw barrel. We have a full stock of our top selling conical twin screw barrel models and support 7-day delivery. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

HUACHEN Screw Barrel Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;